In the wide application of electronic devices, capacitors, as one of the key components, play an important role in storing charge and regulating current. Among many capacitor types, box film capacitors have shown significant advantages in many fields with their unique structure and excellent performance. The following will introduce you to the basic composition, classification and significant advantages of box film capacitors.

First, the basic composition of the box film capacitor

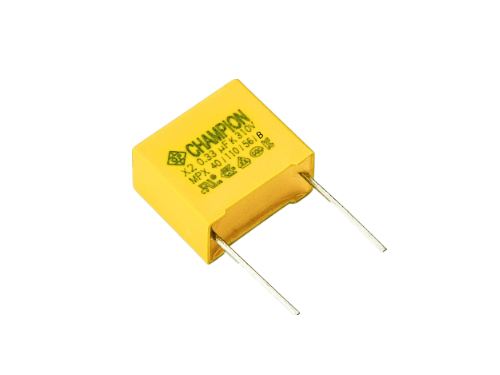

The box film capacitor is a capacitor that is wound into a cylinder after overlapping a metal foil as electrode with a plastic film such as polyethyl ester, polypropylene, polystyrene or polycarbonate from both ends, and is finally encapsulated in a box shell. According to the type of plastic film used, film capacitors are divided into polyethyl ester capacitors (also known as Mylar capacitors), polypropylene capacitors (also known as PP capacitors), polystyrene capacitors (also known as PS capacitors) and polycarbonate capacitors. This structure makes the thin film capacitor not only have high insulation impedance and wide frequency response, but also have the characteristics of non-polarity.

Second, the classification of cassette film capacitors

Box film capacitors are mainly divided into DC film capacitors and AC film capacitors. Dc thin film capacitors are mainly used in DC power supply circuits, including general class, suppression power electromagnetic interference class, pulse class and precision class. Ac film capacitors are mainly used in AC power supply circuits, such as motor start-up and power factor compensation.

Third, the advantages of box film capacitors

1. Non-polar design: Unlike aluminum electrolytic capacitors and tantalum capacitors, thin film capacitors do not need to distinguish between positive and negative electrodes, which greatly simplifies the circuit design and installation process, and reduces the risk of damage caused by polar connections.

2. Self-healing performance: Film capacitors have excellent self-healing properties. When there is an electrical energy defect on the capacitor film or the insulator is broken down due to overvoltage, the surrounding evaporation coating will immediately oxidized, so that the capacitor will restore the insulation state, improving its reliability and service life.

3. Long life: The design life of film capacitors is usually very long, high-quality film capacitors such as KYET brand, the design life of up to 100,000 hours, almost no need to worry about its damage due to long-term use.

4. Excellent frequency characteristics: the film capacitor has a wide frequency response, small media loss, suitable for high-frequency circuits, to ensure that the signal is not distorted during transmission.

5. Wide range of applications: Due to its excellent performance, box film capacitors are widely used in many industries such as electronics, home appliances, communications, electric power, electrified railway, hybrid electric vehicles, wind power generation and solar power generation.

Fourth, the practical application of cassette film capacitors

Box-type film capacitors are particularly used in circuits such as integrated circuit boards and analog circuits. Especially in the aspect of signal crosslinking, thin film capacitors ensure the stability and accuracy of signals during transmission because of their low dielectric loss and wide frequency response. In addition, in power electronic circuits, thin film capacitors also play an important role in power current buffering, clamping, resonant bypass and inhibiting the electromagnetic interference of the power supply.