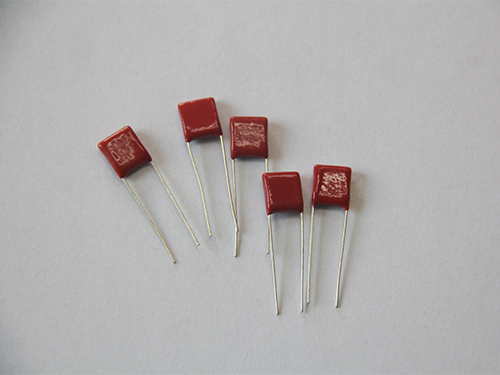

In the world of electronic components, capacitors are key components for storing charge and regulating current, and their performance is directly related to the stability and efficiency of the entire electronic system. Among many capacitor types, metallized film capacitors, with their unique structure and excellent performance, have gradually surpassed the traditional ordinary film capacitors and become the best choice in many application fields. The following will introduce you to the unique features of metallized film capacitors compared to ordinary film capacitors to reveal why they have a place in the market.

First, the structure and principle of metallized film capacitor

Metallized film capacitors use an extremely thin metal film as an electrode on the surface of polyester or polypropylene film, replacing the traditional practice of metal foil as an electrode. This innovative design not only significantly reduces the size of the capacitor, but also brings a series of other performance improvements. The core advantage of metallized film capacitors is their so-called "self-healing" characteristics, that is, when a certain point of the capacitor film is broken down due to defects or overvoltage, the metallized layer of the breakdown point will instantly melt and vaporize under the action of an arc, forming a tiny metal-free zone, so that the two pole plates of the capacitor re-insulate each other, thus restoring the normal operation of the capacitor. The reliability and service life of the capacitor are greatly improved.

Second, the unique advantages of metallized film capacitors

1. High precision and stability: metallized film capacitors can achieve 1% or higher accuracy, and long-term stability and temperature stability is excellent, suitable for circuits with high capacitance value accuracy requirements.

2. High frequency response: metalized film capacitors have a wide range of operating frequencies, from tens of Hertz to hundreds of megahertz, which is suitable for high frequency and fast switching application scenarios, such as communication equipment, high frequency power supplies, etc.

3. High temperature resistance: metallized film capacitors can work normally at higher temperatures and have good thermal stability, which is suitable for electronic devices operating in high temperature environments.

4. Self-healing characteristics: As mentioned earlier, metallized film capacitors have unique self-healing characteristics, which can self-repair the breakdown caused by defects or overvoltage to a certain extent, greatly improving the reliability and service life of capacitors.

5. Small volume: Because the thickness of the metallized film layer is much less than that of the metal foil, the volume of the metallized film capacitor is significantly reduced after winding, which is suitable for compact electronic devices and circuits, helping to reduce the volume and weight of the overall system.

Third, the application field of metallized film capacitors

These unique advantages of metallized film capacitors make them have wide application prospects in many fields. In the field of communications, the high frequency response and stability of metallized film capacitors make them ideal for high-speed data transmission and signal processing circuits. In the field of power electronics, the high temperature stability and self-healing properties of metallized film capacitors make them indispensable components in power electronic devices. In addition, in industrial automation, automotive electronics, aerospace and other fields, metallized film capacitors also play an important role.